#Logistics automation and smart warehouses

Explore tagged Tumblr posts

Text

The future of logistics is now: AI & Automation trends to watch in 2025

Problem: Traditional Logistics Can’t Keep Up Anymore

The logistics industry has always been the backbone of global trade. But in 2025, old systems are simply not fast, smart, or flexible enough to keep up. Rising fuel costs, unpredictable demand, labor shortages, and supply chain disruptions have pushed logistics companies to rethink operations.

Manual tracking, slow warehouse operations, and disconnected systems lead to delivery delays, increased costs, and unhappy customers. To stay competitive, logistics providers need more than just manpower, they need intelligence and automation.

Promise: Ai and automation are transforming the game in 2025

The good news? AI-powered logistics and smart automation are no longer futuristic concepts , they’re reality in 2025. From autonomous delivery vehicles to predictive inventory and smart route optimization, AI in logistics is unlocking new levels of efficiency, speed, and visibility.

Companies adopting logistics automation in 2025 are seeing:

Up to 30% faster deliveries

Real-time tracking with 99% accuracy

Reduced fuel and labor costs

Smarter demand forecasting and fewer stockouts

📊 Proof: real-world applications of Ai in logistics (2025)

Let’s break down how AI and automation are actively reshaping logistics today:

1. Smart warehousing and robotics

Modern warehouses in 2025 use AI-powered robots to pick, pack, and sort packages. These systems reduce human error and boost throughput.

Example: Amazon’s AI-driven robotic warehouses process thousands of orders per minute with near-perfect accuracy.

2. Predictive Analytics and Inventory Management

AI tools now predict demand trends based on historical data, weather patterns, and customer behavior helping companies avoid overstocking or stockouts.

Stat: Companies using predictive logistics AI report up to 40% reduction in excess inventory.

3. Autonomous Delivery Vehicles & Drones

Self-driving trucks and drones are no longer pilot projects; they're actively delivering goods in urban and rural areas.

Example: FedEx and UPS are deploying AI-guided autonomous trucks for regional deliveries in the U.S.

4. AI Route Optimization

AI platforms like ClearMetal and Locus use real-time data to optimize delivery routes in minimizing fuel consumption and delivery time.

Result: Businesses save thousands monthly by avoiding traffic, delays, and inefficient planning.

Proposal: Why you should embrace logistics automation in 2025

If you’re in the logistics business or rely heavily on shipping and supply chains, now is the time to act.

Here’s what you can do:

Audit Your Current Tech Stack

Identify where manual systems are costing you time and money. Focus on warehouse operations, delivery tracking, and customer service.

Invest in Scalable AI Solutions

Start with tools that offer immediate ROI such as AI route planners or automated inventory systems.

Partner with a Logistics Tech Expert

Don’t go it alone. Collaborate with a logistics software development company that understands AI in logistics 2025 and can build custom automation solutions for your business.

Train your team for the Ai shift

Technology is only powerful if your people can use it. Upskill your staff in AI-powered systems and digital tools.

Conclusion :

The logistics industry in 2025 is smarter, faster, and more data-driven than ever thanks to AI and automation. Businesses that invest today in intelligent logistics solutions will gain a competitive edge, reduce operational costs, and exceed customer expectations.

Don’t let outdated systems slow you down. Embrace the AI revolution in logistics now.

#“latest logistics innovations 2025”#“AI and automation in supply chain”#“future of logistics industry”#“transportation tech innovations”#logistics mobile app development trends”#Logistics innovations 2025#Supply chain trends 2025#Future of logistics industry#Smart logistics solutions#Emerging logistics technologies#Top logistics tech trends for 2025#Logistics automation and smart warehouses#Sustainable logistics practices in 2025

1 note

·

View note

Text

Guide for Importers on Manufacturing Control

Efficient Manufacturing Control in China

1. Understand the Chinese Manufacturing Environment:

Diverse Ecosystem: China offers a vast range of manufacturers, from small workshops to large factories. This variety is beneficial but also poses challenges in ensuring consistent quality.

IP Concerns: Despite improvements, IP protection in China can be inconsistent, requiring robust measures to safeguard your innovations.

Regulatory Landscape: China’s complex and changing regulations make compliance crucial to avoid fines and reputational damage.

Quality Control: While quality has improved, some sectors still prioritize quantity over quality. Rigorous quality protocols are essential.

Labor & Costs: Labor costs are rising, pushing manufacturers toward automation. Infrastructure is robust, but supply chains can be disrupted by natural disasters or policy changes.

Government Policies: China’s government heavily influences manufacturing through policies and incentives, which can affect costs and market access.

2. Build a Strong Foundation:

Supplier Selection: Choose reliable suppliers through thorough due diligence, including factory visits and financial checks.

Clear Communication: Provide detailed specifications and maintain open communication to avoid misunderstandings.

Quality Management: Implement a Quality Management System (QMS) and conduct regular audits to ensure consistent product quality.

Strong Relationships: Develop long-term partnerships with suppliers to build trust and collaboration.

3. Implement Effective Control Strategies:

QA & QC: Establish a robust QA/QC framework to ensure consistent product quality.

Supplier Development: Invest in your suppliers’ capabilities to improve quality and efficiency.

Risk Management: Prepare for disruptions with backup plans and diversified suppliers.

Contractual Coverage: Clearly define product specifications and include IP protections in contracts.

Third-Party Verification: Use third-party inspections to ensure compliance and quality.

4. Manage Logistics & Supply Chain:

Transportation: Choose the best transport mode and routes to minimize costs and delays.

Warehousing & Inventory: Optimize warehouse locations and use management systems to track inventory.

Customs & Documentation: Ensure compliance with customs regulations and prepare accurate documentation.

Supply Chain Visibility: Use technology to monitor shipments and collaborate with suppliers.

Risk Assessment: Develop contingency plans for disruptions like natural disasters or strikes.

5. Overcome Common Challenges:

Language & Cultural Barriers: Hire experts to bridge gaps in communication and cultural understanding.

IP Protection: Secure your IP with patents, trademarks, and NDAs; monitor for infringements.

Regulatory Compliance: Stay updated on regulations and partner with local experts for compliance.

Supply Chain Disruptions: Diversify suppliers, maintain sufficient inventory, and use smart tools for monitoring.

6. Continuous Improvement:

Use data analytics to track trends and improve processes.

Regularly evaluate supplier performance and invest in employee training.

Embrace technology to enhance communication and efficiency.

7. Build a Culture of Quality:

Encourage employees to propose improvements.

Reward contributions to quality enhancement.

Focus on exceeding customer expectations.

Conclusion: Effective manufacturing control in China requires ongoing effort, attention, and adaptation. Invest in strong practices to improve product quality, reduce costs, protect your brand, and optimize your supply chain.

3 notes

·

View notes

Text

Larry Savage Birmingham About Logistics Challenges And How To Overcome Them

Logistics managers are now more aware of the need to obtain vital information instantly due to the pandemic. Additionally, it encouraged warehouse managers to be proactive in mitigating risks related to supply and demand. Today, machine learning software that analyzes real-time data can help prevent both overstock and out-of-stock. This is similar to IoT sensors assisting transportation businesses in tracking goods throughout the route. So, to learn more, read Larry Savage Jr Birmingham – Challenges That Necessitate The Need For An Organized Logistics Industry to level up your business performance.

Strengthen communication at all levels

A vital component of surviving in business is anticipating logistical obstacles and knowing how to overcome them. You should include improving communication with the participants in your global supply chain in your planning. You might even wish to create connections with far-off logistical companies to increase your marketing reach if your company is local. In order to stay informed about the state of the resources supporting your products and market, it's critical to keep in constant contact with your suppliers.

Establish standards for suppliers and partners

If businesses follow different standards, it could confuse some of them when arranging many deliveries daily with several supply chain managers. Logistics operations are considerably more streamlined and coherent when every service follows the same loading and unloading procedures. Supply chain visibility can also be maximized for all participants in this coordination through smart technology and interconnected electronic networks.

Invest in the right technology

Companies today are also overspending on the latest software and hardware developments due to the quick changes in business technology. Spending less on technology to achieve maximum efficiency is now possible if you use cloud technologies.

If your business is operating on a tight budget, cloud services offer the most economical options. A warehouse might think about collaborating with logistics industry specialists if it needs additional flexibility, scalability, or experience.

Using third-party logistics providers to carry goods to markets is one way for businesses that can't afford to invest in creating a logistics service that makes use of automation, robots, and artificial intelligence.

Reduce warehouse management errors

An infrastructure's likelihood of errors decreases as it becomes more digital through automation or improved access to pertinent real-time data.

Adopting warehouse management software with integrations to new and innovative technologies like 5G, AI, and IoT has become crucial in this century. You can use these technologies to gather and archive important logistics data.

Proper placement of warehouse inventory products is also crucial to avoid a cascade of disruptions.

Then, to prepare items for delivery, they must be carefully chosen and packed. Incomplete orders and incorrect delivery information are two common order fulfillment mistakes that still happen. Warehouse managers can effectively decrease these errors by using more vigilant supervision and enhanced picking and packing confirmation protocols.

Final thoughts

In the future, meeting customer needs will be the hardest task for the logistics industry. So, improving warehouse structure and layout by analyzing logistics will help you. Lastly, don’t read Larry Savage Birmingham — Know About The Basics Of Stock Options Trading to keep your fortunes thriving.

#Larry Savage Birmingham#Logistics Challenges#Logistics Expert#Logistics Industry#business owner#business ideas#business strategy

3 notes

·

View notes

Text

Asset Tracking System – Streamlining Operations and Improving Efficiency

How AIDC Smart Systems Streamline Operations with Asset Tracking in 2025

In 2025, businesses across India are embracing digital transformation to improve their operational efficiency. One of the most effective tools driving this change is the advanced tracking system offered by AIDC Technologies India. By leveraging smart asset tracking solutions, AIDC helps companies gain real-time visibility into their assets, reduce losses, and streamline workflows. This technology is making a significant impact in sectors such as manufacturing, logistics, healthcare, and retail.

Real-Time Asset Visibility with AIDC’s Advanced Tracking Solutions

One of the core strengths of AIDC’s tracking system is its ability to provide real-time visibility into asset locations and conditions. Whether it’s machinery on a factory floor, inventory in a warehouse, or equipment across multiple sites, the system continuously monitors each asset. This real-time tracking allows businesses to respond quickly to issues like asset misplacement or downtime, ensuring smooth and uninterrupted operations.

Enhancing Operational Efficiency Through AIDC Asset Tracking Systems

Operational efficiency depends on having the right resources at the right place and time. AIDC’s tracking system automates asset monitoring, reducing manual checks and errors. This automation speeds up processes such as inventory counts, maintenance scheduling, and asset allocation. By freeing up employee time from tedious tasks, businesses can focus on growth and customer satisfaction.

AIDC’s Role in Reducing Costs Using Smart Asset Tracking Technology

Cost savings is a major benefit of adopting AIDC’s tracking system. With precise asset location data, companies minimize losses caused by theft, misplacement, or underutilization. The system also supports predictive maintenance by alerting managers before equipment failure occurs, preventing expensive downtime. By optimizing asset use and maintenance, businesses experience lower operational costs and higher return on investment.

RFID and Barcode Technologies in AIDC’s Asset Tracking Solutions

AIDC integrates RFID and barcode technologies within their tracking system to provide flexible and reliable asset identification. RFID tags allow for contactless, bulk scanning of multiple assets, which is especially useful in large warehouses or busy production lines. Barcodes offer a cost-effective solution for smaller inventories or specific asset groups. This combination ensures that businesses can tailor their asset tracking approach based on their unique requirements.

Cloud-Enabled Asset Tracking Platforms by AIDC Technologies India

AIDC’s tracking system is cloud-enabled, offering the advantage of remote access and centralized data management. Managers can view asset information anytime, anywhere, through secure web portals or mobile apps. The cloud infrastructure also ensures automatic data backups, seamless software updates, and easy scalability. This modern approach supports businesses operating across multiple locations or those planning future expansion.

Improving Inventory and Supply Chain Management with AIDC Smart Systems

Effective inventory and supply chain management rely heavily on accurate asset tracking. AIDC’s tracking system provides end-to-end visibility, helping businesses optimize stock levels and reduce excess inventory. It also supports just-in-time inventory practices by alerting when replenishment is needed. This reduces storage costs and improves cash flow while ensuring customer demand is met promptly.

Predictive Maintenance and Asset Lifecycle Management by AIDC

Managing asset lifecycles is critical for maximizing productivity and cost-efficiency. AIDC’s tracking system collects real-time data on asset performance and usage, enabling predictive maintenance. By forecasting potential failures or wear and tear, businesses can schedule timely repairs and avoid unexpected breakdowns. This proactive approach extends asset life and reduces maintenance expenses.

Security and Compliance Features in AIDC Asset Tracking Systems

Security and compliance are top priorities for many industries. AIDC’s tracking system includes features such as access control, audit trails, and tamper alerts. These help protect valuable assets and sensitive information from unauthorized access or misuse. The system also assists in meeting regulatory requirements by maintaining detailed records of asset movements and conditions.

Mobile Asset Tracking Solutions Offered by AIDC for On-the-Go Monitoring

In today’s fast-paced business environment, mobility is essential. AIDC provides mobile-compatible tracking systems that allow field workers and managers to scan, update, and monitor assets using smartphones or tablets. This flexibility improves data accuracy and ensures that asset information is up to date regardless of location. Mobile tracking also enhances communication between teams and supports faster decision-making.

Data Analytics and Reporting Capabilities of AIDC Smart Systems

Beyond tracking, AIDC’s system offers powerful data analytics and reporting tools. Businesses can generate customized reports to analyze asset utilization, maintenance trends, and operational bottlenecks. These insights enable informed decision-making and continuous improvement. By leveraging data effectively, companies can identify opportunities for cost savings and productivity gains.

Customizable Asset Tracking Solutions Tailored for Diverse Industries by AIDC

Every industry has unique asset management challenges. AIDC understands this and offers customizable tracking systems to fit different sectors such as manufacturing, healthcare, logistics, retail, and government. The flexibility to adapt to specific workflows, compliance standards, and asset types makes AIDC’s solutions versatile and effective across diverse business environments.

How AIDC’s Smart Asset Tracking Systems Support Digital Transformation

AIDC’s tracking system is more than just a tool; it is a strategic enabler of digital transformation. By automating asset management processes and providing real-time data, AIDC helps businesses move away from paper-based systems and manual logs. This shift improves accuracy, reduces delays, and enhances collaboration. Ultimately, it positions companies to compete successfully in the digital age.

Success Stories: Businesses Benefiting from AIDC Asset Tracking Solutions

Many businesses across India have already benefited from implementing AIDC’s tracking system. From reducing equipment loss in hospitals to optimizing warehouse operations for e-commerce companies, the results have been impressive. Clients report improved asset visibility, faster audits, reduced operational costs, and higher employee productivity. These success stories demonstrate the tangible value of AIDC’s technology.

Why AIDC is a Leading Provider of Asset Tracking Systems in India

AIDC Technologies India combines extensive industry experience with continuous innovation to provide best-in-class tracking systems. Their commitment to customer satisfaction, customized solutions, and robust technical support sets them apart. With a strong presence across India and a growing global footprint, AIDC remains a trusted partner for businesses seeking to streamline operations and improve efficiency through smart asset tracking.

Ready to upgrade your asset security?

Ready to streamline your operations and boost efficiency? Book your personalized demo of AIDC’s Tracking System today!

#EfficientAssetManagement#TrackAssetsSmartly#AIDCAssetSolutions#DigitalAssetControl#RealTimeAssetTracking#SmartTrackingSolutions#AssetTrackingMadeEasy#InventoryToAssetAutomatio

0 notes

Text

Top Wholesale ERP Software in Calgary for Smarter Inventory and Order Management

Wholesale and distribution businesses in Calgary face daily challenges in managing complex inventory, tracking orders, handling logistics, and staying competitive in a fast-moving market. Disconnected systems and manual processes often lead to delays, stockouts, or excess inventory. That’s where Smart Stream ERP steps in—with powerful, industry-specific Wholesale ERP software in Calgary designed to streamline your operations from warehouse to delivery.

Why Wholesale ERP Software Matters

Running a wholesale or distribution business requires real-time visibility, accurate forecasting, and seamless coordination across departments. Traditional tools often fall short, leading to operational inefficiencies. Our Wholesale ERP software centralizes your data, automates tasks, and improves accuracy in every part of the supply chain.

From inventory control and order fulfillment to customer management and invoicing, Smart Stream ERP provides the tools needed for efficiency and growth.

Smarter Inventory Management with ERP

Inventory is the backbone of any wholesale operation. With ERP software for wholesale and distribution, businesses can gain real-time insights into stock levels, reorder points, and warehouse performance.

Key inventory features include:

Automated stock tracking and reorder alerts

Batch and lot tracking for traceability

Multiple warehouse and location management

Demand forecasting based on real-time sales data

Our wholesale and distribution ERP software in Calgary helps reduce overstock, prevent stockouts, and improve customer satisfaction with timely deliveries.

Better Order Management with ERP Software for Distribution

Order processing is another area where errors and delays can cost you sales. ERP software for distribution in Calgary simplifies the entire order lifecycle—from quote to invoice.

Smart Stream ERP allows you to:

Automatically process and track orders across channels

Connect sales, inventory, and finance in real-time

Handle bulk and repeat orders with ease

Generate accurate invoices and shipping documents instantly

With smarter order management, Calgary wholesalers can boost efficiency and eliminate manual bottlenecks.

Tailored ERP Software for Wholesale and Distribution in Calgary

Smart Stream ERP is built with the needs of Calgary’s wholesale and distribution sector in mind. Our ERP software for wholesale and distribution in Calgary is fully customizable and scalable, whether you manage a small warehouse or a large multi-location supply chain.

You get:

Role-based dashboards and reporting

Seamless integration with eCommerce and logistics platforms

User-friendly interface with mobile access

Robust customer support and local expertise

Upgrade Your Wholesale Business Today Don’t let outdated systems hold your business back. Choose Smart Stream ERP—the trusted provider of wholesale ERP software in Calgary. Whether you need ERP software for distribution, or a complete wholesale and distribution ERP software solution, we help you gain full control and grow with confidence.

Contact Smart Stream ERP now to book your demo and take the first step toward smarter inventory and order management.

#eCommerce ERP integration in Calgary#ERP for eCommerce in Calgary#POS ERP solutions for retailers in Calgary#Retail ERP software in Calgary

0 notes

Text

Automatic Strapping Machine Market Overview: Trends and Forecast 2025–2030

The Automatic Strapping Machine Market is entering a transformative period driven by rapid industrial automation, booming e-commerce, and an urgent need for efficient, sustainable packaging solutions. These machines, used to apply a strap around products or packages for secure transportation and storage, are increasingly vital across sectors like logistics, food & beverage, pharmaceuticals, and manufacturing.

As industries prioritize operational efficiency and consistent packaging quality, automatic strapping machines are becoming essential equipment in modern production and distribution environments. From high-speed logistics hubs to palletizing in heavy industries, the demand for automated, smart, and cost-effective strapping solutions is expected to grow steadily through 2030.

Market Size and Forecast (2025–2030)

The Automatic Strapping Machine Market is projected to grow at a compound annual growth rate (CAGR) of 6% to 8% between 2025 and 2030.

The global market value is expected to exceed USD 4 billion by 2030, driven by automation in packaging processes, labor shortages, and demand for operational efficiency.

Asia-Pacific is anticipated to lead in volume, while North America and Europe will drive innovation and premium automation solutions.

Key Market Trends

1. Rise of Automation in Packaging Lines

Manufacturers and warehouses are upgrading from manual and semi-automatic to fully automatic strapping machines to:

Reduce manual labor

Enhance packaging speed

Ensure uniformity and reliability

2. Booming E-commerce and Logistics

The surge in parcel shipments and warehousing activity is fueling demand for machines that can handle high throughput, variable sizes, and fast turnaround.

3. Focus on Sustainable Packaging

Companies are shifting toward recyclable strapping materials and energy-efficient machines to meet environmental regulations and reduce waste.

4. Smart Technology Integration

Strapping machines with IoT, remote diagnostics, data analytics, and PLC control systems are in demand, especially in smart factories and Industry 4.0 environments.

5. Customization and Versatility

Modern machines are designed to handle a variety of product sizes, shapes, and materials across different industries.

Regional Market Overview

North America

Strong adoption of automation in warehousing and 3PL operations

High demand for smart and network-integrated strapping machines

Asia-Pacific

Dominates global volume due to manufacturing and export activity

Fast-growing e-commerce and food packaging sectors in India and Southeast Asia

Europe

Focused on sustainability and compliance with EU packaging efficiency norms

Higher investment in fully automatic systems for long-term ROI

Market Segmentation Snapshot

SegmentTrendsBy TypeIncreasing preference for fully automatic over semi-automaticBy End UseLogistics, food, industrial packaging, and pharmaBy MaterialShift toward recyclable plastic straps and PETBy OperationRise in PLC-based, programmable machines

Competitive Landscape

The market features a mix of global manufacturers and regional players offering specialized solutions. Major players are investing in:

R&D for smart technology integration

Partnerships with packaging OEMs and automation firms

After-sales services and remote maintenance tools

Leading Companies include:

Signode Industrial Group

Mosca GmbH

StraPack Inc.

FROMM Packaging Systems

Transpak Equipment Corp.

Opportunities and Growth Drivers

E-commerce growth demanding rapid, secure parcel handling

Labor shortages encouraging automation in warehouses and factories

SME adoption in developing economies with compact, cost-efficient models

Integration with warehouse management systems (WMS) and smart logistics solutions

Challenges

High initial investment in fully automatic systems

Maintenance and training requirements for advanced machinery

Infrastructure limitations in rural and developing regions

Market Outlook 2025–2030

Increased penetration in small and mid-sized enterprises due to compact machine designs and leasing models

Adoption of AI and robotics for predictive maintenance, real-time adjustments, and autonomous operation

Eco-friendly innovation: solar-powered machines, biodegradable straps, and energy-saving features

Regional manufacturing hubs emerging in Southeast Asia, Latin America, and Africa

Conclusion

The Automatic Strapping Machine Market is on a robust growth trajectory, propelled by automation trends, packaging standardization, and increasing demand for efficiency across global supply chains. As businesses embrace smarter, faster, and more sustainable packaging solutions, automatic strapping machines will remain at the forefront of industrial and logistics transformation from 2025 to 2030.

0 notes

Text

Secrets of Successful Brands: Leveraging 3PL eCommerce Fulfillment Like a Pro

In the highly competitive world of eCommerce, the ability to deliver products swiftly, affordably, and efficiently is not just a luxury, it’s a necessity. The most successful brands have uncovered a secret weapon to gain a competitive edge: Third-Party Logistics (3PL) eCommerce fulfillment. This comprehensive guide reveals how thriving businesses strategically use 3PL services to streamline operations, improve customer satisfaction, and scale rapidly.

What is 3PL eCommerce Fulfillment and Why It Matters

3PL eCommerce fulfillment involves outsourcing logistics processes such as warehousing, picking, packing, and shipping to a specialized third-party provider. This allows brands to focus on what they do best: product development, marketing, and customer engagement.

Key benefits of 3PL include:

Scalability and flexibility during seasonal demand spikes

Reduced overhead costs by eliminating the need for in-house warehousing

Improved delivery times with distributed fulfillment centers

Access to advanced logistics technology for real-time inventory tracking

How Top Brands Choose the Right 3PL Partner

Selecting the right 3PL provider is a strategic decision that directly impacts customer satisfaction and profitability. The most successful eCommerce brands evaluate partners based on the following criteria:

1. Geographic Fulfillment Network

Brands look for 3PLs with multiple strategically located warehouses. This reduces shipping times and costs, ensuring faster last-mile delivery.

2. Integration Capabilities

Successful companies choose 3PLs that integrate seamlessly with their eCommerce platforms, such as Shopify, WooCommerce, Magento, or BigCommerce. API connectivity and automated syncing eliminate manual errors.

3. Real-Time Inventory Management

A reliable 3PL provides real-time inventory tracking, automatic stock level updates, and detailed analytics. Brands use this data to manage supply chains efficiently and avoid stockouts or overstocking.

4. Transparent Pricing Models

Top brands demand clear, transparent pricing without hidden fees. Whether it’s per-unit fulfillment pricing, storage fees, or packaging costs, knowing the exact cost structure helps in financial planning.

Cost Optimization Through 3PL Fulfillment

Managing logistics in-house often results in higher fixed costs. Outsourcing to a 3PL provider enables brands to:

Convert fixed costs to variable costs, scaling expenses with demand

Leverage volume shipping discounts through bulk negotiations

Minimize capital investment in warehouses, equipment, and labor

Successful brands allocate these savings into growth-driving areas like marketing, product innovation, and customer retention.

How to Onboard a 3PL Partner for Your eCommerce Brand

Transitioning to a 3PL involves meticulous planning. Here’s how smart brands handle onboarding:

Audit current logistics processes and set clear KPIs

Choose a 3PL provider with proven experience in your product category

Set up integrations with your eCommerce and inventory management systems

Train internal teams on the new logistics workflows

Monitor performance metrics such as order accuracy, delivery times, and cost per shipment

Brands that leverage 3PL eCommerce fulfillment strategically enjoy faster growth, stronger customer loyalty, and operational excellence. By outsourcing logistics to specialized providers, companies unlock the freedom to scale and innovate.

Whether you're a startup looking to grow or an established enterprise optimizing operations, the right 3PL partner is a key differentiator in today’s fast-paced eCommerce landscape.

For original post visit: https://vintfint.com/blogs/66417/Secrets-of-Successful-Brands-Leveraging-3PL-eCommerce-Fulfillment-Like-a

0 notes

Text

Automated Tow Tractor Market Research Report, Demand and Future Trends Till 2037

The Automated Tow Tractor Market was valued at USD 3.9 billion in 2024 and is expected to witness significant growth, reaching approximately USD 8.6 billion by 2037. This indicates a steady compound annual growth rate (CAGR) of 7.9% over the forecast period from 2025 to 2037.The upward trend is primarily driven by the widespread adoption of automation in industrial logistics, increased demand for material handling efficiency, and labor cost reduction across key sectors.

Automated Tow Tractor Industry Demand

The Automated Tow Tractor Market involves the development and deployment of driverless or semi-autonomous towing vehicles used for transporting materials within manufacturing facilities, warehouses, airports, and logistics hubs. These machines are designed to follow predefined paths or operate intelligently through real-time navigation systems, significantly reducing human intervention.

The market's expansion is supported by the following key demand factors:

Cost-Effectiveness: Automated tow tractors help cut down operational costs by minimizing labor dependency and improving energy efficiency.

Operational Simplicity: These machines are easy to integrate into existing systems, often with minimal disruption, offering high adaptability across diverse environments.

Reliability and Consistency: With automation, error rates in material transport are greatly reduced, and performance remains consistent throughout the operating cycle.

Long Service Life: Automated tow tractors are designed for durability and often require less maintenance than manual systems, ensuring long-term value for businesses.

Request Sample@ https://www.researchnester.com/sample-request-3063

Automated Tow Tractor Market: Growth Drivers & Key Restraint

Growth Drivers –

Expansion of Industrial Automation and Smart Warehousing As companies embrace Industry 4.0, the integration of automated tow tractors into logistics and production lines has become a key strategy for boosting productivity and minimizing downtime.

Rising Labor Costs and Skilled Workforce Shortage With increasing wages and a shortage of skilled labor, businesses are turning to automated solutions to maintain operational efficiency and reduce dependency on human resources.

Technological Innovations in Vehicle Autonomy Advancements in navigation, battery technology, and real-time tracking have made tow tractors more efficient, safer, and suitable for a broader range of industrial applications.

Restraint –

High Initial Investment The initial investment required for deploying automated tow systems such as modifying existing infrastructure and integrating specialized software can be a barrier for small and medium-sized businesses.

Complexity in Integration with Legacy Systems Older warehouses or manufacturing facilities may face compatibility issues when incorporating automated tow tractors, requiring substantial retrofitting.

Limited Flexibility in Dynamic Environments While effective in structured settings, automated tow tractors can struggle with unexpected obstacles or changes in route, limiting their use in unstructured environments.

Automated Tow Tractor Market: Segment Analysis

Segment Analysis by Product Type –

Electric: These models dominate the market due to environmental regulations and the push toward sustainable operations.

Hybrid: A smaller but growing segment, hybrid tow tractors offer flexibility and longer operating times, making them ideal for mixed-use environments.

Traditional (Fuel-based): Though declining in preference, they remain in use in industries where high power and long-duration performance are critical and charging infrastructure is limited.

Each type exhibits varying adoption rates based on industry needs, operational costs, and environmental regulations.

Segment Analysis by End‑User –

Logistics: Logistics companies are early adopters, using tow tractors to streamline internal goods movement and enhance last-mile delivery efficiency.

Manufacturing: Tow tractors play a vital role in moving raw materials and components between assembly lines, improving workflow and reducing production delays.

Airports: Used for baggage handling and cargo movement, especially in high-traffic airports looking to optimize space and reduce turnaround time.

Warehousing: Automation in warehouses has skyrocketed, with tow tractors helping manage inventory transport seamlessly.

Other: Includes agriculture, retail distribution centers, and healthcare sectors, which are gradually adopting automated systems for specific material handling needs.

Each end-user segment showcases unique requirements, contributing to varied performance and adoption patterns in the market.

Automated Tow Tractor Market: Regional Insights

North America

North America is a leading region in the automated tow tractor space due to robust industrial infrastructure, a strong focus on automation, and the presence of major manufacturers. The region benefits from high investment in AI-driven material handling and consistent warehouse automation trends, particularly in the U.S.

Europe

Europe follows closely, driven by stringent environmental regulations, high labor costs, and a strong automotive manufacturing base. Germany, France, and the Netherlands are at the forefront of adopting electric and hybrid tow tractor models for sustainable logistics and smart factories.

Asia-Pacific (APAC)

APAC represents the fastest-growing market, propelled by rapid industrialization, expanding e-commerce, and supportive government policies for automation. China, Japan, South Korea, and India are investing heavily in smart logistics infrastructure, with increasing demand from manufacturing and export-oriented sectors.

Top Players in the Automated Tow Tractor Market

The Automated Tow Tractor Market is highly competitive and features several key players that dominate global operations and innovation. Prominent companies include Tesla, Inc., Hyster-Yale Materials Handling, JBT Corporation, Kion Group AG, Linde Material Handling, Raymond Corporation, CVS Ferrari, Baoli Forklifts, Hangcha Group, Daimler AG, XPO Logistics, Hyundai Heavy Industries, Doosan Industrial Vehicle, and HANGCHA. These firms are actively expanding their product portfolios, investing in R&D, and forming strategic partnerships to strengthen their market presence and technological capabilities.

Access Detailed Report@https://www.researchnester.com/reports/automated-tow-tractor-market/3063

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Explore how AI-powered autonomous mobile robots (AMRs) are revolutionizing warehouse operations. From intelligent package handling to seamless logistics automation, this is the future of modern robotics. Designed for tech innovators and automation engineers seeking real-world robotics solutions. Learn more at www.auckam.com – your partner in smart robotics and intelligent automation.

#ModernRobotics#WarehouseAutomation#AutonomousRobots#SmartLogistics#AIinRobotics#RoboticsEngineering#AMR#IndustrialAutomation#IntelligentAutomation#TechInnovation#SmartWarehousing#RoboticsSolutions#EdgeAI#IoTInLogistics#RobotInWarehouse

0 notes

Text

How the Automated Guided Vehicle Is Driving the Future of Logistics

In the era of automation, one device—the automated guided vehicle, or AGV—is subtly but significantly changing the landscape of manufacturing and warehouse operations. Despite their lack of ostentation, these clever robots are the unsung heroes of effective operations, providing a more intelligent method of moving materials, lowering human error, and streamlining workflows.

What is anautomated guided vehicle, then? Imagine it as an autonomous car that follows predetermined routes in factories, distribution hubs, and warehouses. It's a smart cart with sensors, software, and occasionally lasers to help it safely navigate intricate routes rather than an arm-wielding robot or self-driving automobile. The outcome? Consistent output, fewer accidents, and 24-hour operations.

AGVs are ideal for time-consuming, repetitive jobs like moving products, bins, or pallets from one end of a facility to the other. This is particularly helpful in industries where accuracy and dependability are essential, such as the automotive, food and beverage, FMCG, and pharmaceutical sectors. Additionally, companies can continue operations even during peak hours or night shifts because automated guide vehicles don't require lunch breaks or time off. The versatility of AGVs is what further increases their allure. Routes can be expanded or reprogrammed as activities grow or change without requiring significant alterations or the destruction of floor infrastructure. Additionally, they are scalable, so you can begin with a small fleet and expand it as your company grows. Additionally, cost-effectiveness and safety are crucial in the current competitive environment. By taking over activities involving heavy lifting or the transportation of hazardous materials, AGVs assist reduce workplace injuries and, over time, personnel expenses.

In summary, for any company that is serious about optimizing its warehouse handling equipment, the autonomous guided vehicle is not only a wise investment, but also the next logical step. AGVs are demonstrating that sometimes the best drivers don't have any steering wheels at all, thanks to lean operations and intelligent automation.

0 notes

Text

In today's fast-paced industrial landscape, rolling conveyor systems have become an essential component of efficient material handling. Whether in manufacturing, packaging, or distribution, businesses across the UK are turning to trusted conveyor manufacturers to streamline operations, reduce manual labour, and improve productivity. This blog takes a closer look at what makes rolling conveyor systems vital and highlights why the UK is a hub for world-class manufacturers in this field.

What Are Rolling Conveyor Systems?

Rolling conveyor systems, often referred to as gravity or powered roller conveyors, use cylindrical rollers to transport items from one point to another. Their design allows for the smooth movement of boxes, pallets, and heavy loads with minimal effort. Common in warehouses, assembly lines, and logistics centres, these systems are praised for their durability, modularity, and ease of integration.

Why Choose UK-Based Rolling Conveyor Manufacturers?

The UK’s engineering sector is known for its innovation and high-quality standards. Manufacturers in the UK offer several advantages:

✅ Advanced Technology: Many UK manufacturers utilise cutting-edge automation, IoT integration, and smart controls in their conveyor solutions.

✅ Customisation: From bespoke designs to modular systems, UK companies can tailor conveyor solutions to fit specific industry needs.

✅ Compliance & Safety: British manufacturers adhere strictly to ISO and CE standards, ensuring safety and legal compliance.

✅ Sustainability: There's a growing focus on energy-efficient and low-maintenance conveyor designs, supporting environmental goals.

Leading Industries Using Rolling Conveyor Systems

Rolling conveyors are versatile and support a wide range of industries in the UK, including:

E-commerce & Fulfilment Centres: Streamlining order picking and packing processes.

Food & Beverage: Ensuring hygienic and efficient movement in processing lines.

Automotive: Supporting assembly lines with heavy-duty roller conveyors.

Pharmaceutical: Enhancing accuracy and compliance in sensitive environments.

Key Features to Look for in a Manufacturer

When choosing a rolling conveyor system manufacturer, consider the following:

Experience & Reputation: Look for companies with proven expertise in industrial automation and a solid track record.

Engineering Support: Top manufacturers provide consultation, design, installation, and maintenance support.

Material Quality: Stainless steel rollers, galvanised frames, and heavy-duty bearings ensure long life.

Innovation: Look for smart conveyors with automated sensors, programmable controls, and AI-driven logistics optimisation.

Trusted Rolling Conveyor Manufacturers in the UK

Several UK-based manufacturers have earned a reputation for delivering excellence:

Conveyor Systems Ltd – Offering tailored conveyor solutions with a focus on retail and warehouse applications.

L.A.C. Conveyors & Automation – Known for advanced automation and intelligent conveyor design.

Monk Conveyors – Specialists in modular conveyors for a wide range of sectors including pharmaceutical and automotive.

Excel Conveyors – Providing cost-effective yet high-performance solutions for SMEs.

Final Thoughts: Investing in the Right Conveyor Partner

Choosing the right rolling conveyor system manufacturer in the UK can transform your operational efficiency. It’s not just about buying equipment—it’s about investing in future-ready logistics infrastructure. From initial design to installation and aftercare, a reliable manufacturer will partner with you to optimise every aspect of material handling.

Frequently Asked Questions

Q1: Are rolling conveyor systems suitable for heavy-duty applications? Yes, heavy-duty rolling conveyors are designed to handle loads exceeding several hundred kilograms, ideal for manufacturing and pallet handling.

Q2: Can these systems be integrated with automation software? Absolutely. Many UK manufacturers offer smart integration with WMS, barcode scanners, and robotics for seamless operations.

Q3: What maintenance do rolling conveyors require? Minimal maintenance is needed—periodic roller checks, belt alignment (for powered systems), and lubrication keep systems running smoothly.

0 notes

Text

The Future of Warehouse Management: How WMS Fuels Growth

The warehouse industry is undergoing a major transformation. With the rapid growth of e-commerce, increasing customer expectations, and continuous advancements in technology, managing warehouses efficiently has never been more critical. In this shifting landscape, a powerful Warehouse Management System (WMS) like Warehouse Solutions for UAE has become an essential part of business success.

Meeting the Demands of Modern Customers

Today’s consumers expect fast delivery, accurate orders, and full visibility into their shipments. This means warehouses must operate with precision and speed. Rubicon WMS Dubai helps businesses meet these rising expectations by streamlining inventory management, improving order accuracy, and integrating smoothly with delivery platforms. The result? Higher customer satisfaction, repeat business, and long-term loyalty.

Keeping Up with E-Commerce Growth

The e-commerce boom has dramatically changed how warehouses function. Businesses now face higher order volumes, complex product assortments, and frequent returns. Warehouse Solutions for UAE is designed to handle these challenges. With smart features like batch picking and return management (reverse logistics), it helps businesses stay competitive and efficient in the fast-paced digital marketplace.

Embracing Automation and Smart Technologies

Automation and AI are redefining warehouse operations. Rubicon WMS seamlessly connects with modern warehouse technologies like robots, pick-to-light systems, and automated guided vehicles (AGVs). These tools minimize manual labor, reduce errors, and boost overall productivity. By automating repetitive tasks, businesses can focus more on strategy and growth.

Built for Growth: Scalable and Flexible

As your business grows, so do the demands on your warehouse. You need a system that can keep up. Warehouse Solutions for UAE is built to scale, handling increased inventory, new locations, and more complex workflows. Its flexible architecture allows for customization, ensuring the system aligns with your specific operational needs now and in the future.

Data-Driven Decisions for Continuous Improvement

In today’s data-driven world, insights are everything. Rubicon WMS provides powerful analytics tools that help identify inefficiencies, track performance, and forecast future needs. From uncovering bottlenecks to optimizing stock levels, these data insights support smarter decision-making and continuous improvement.

Conclusion: Ready for the Future?

The future of warehouse management lies in embracing innovation. By leveraging smart, scalable, and automated systems like Warehouse Solutions for UAE, businesses gain the tools they need to grow, adapt, and exceed customer expectations. Whether you're managing high order volumes or expanding into new markets, Rubicon WMS delivers the flexibility and power needed to stay ahead.

Is your warehouse ready for what’s next? Discover the potential of Rubicon WMS and future-proof your operations today.

0 notes

Text

The Evolving Role of Artificial Intelligence in Warehouse Management Systems

Introduction to AI in Warehouse Management Systems by AIDC

Warehouse operations are becoming more complex with rising demands in logistics, e-commerce, and retail. To meet these challenges, businesses are turning towards Artificial Intelligence in Warehouse Management Systems. AIDC Technologies India is one of the leading names in this transformation, offering smart solutions that automate, optimize, and streamline warehouse tasks. From inventory tracking to predictive analytics, AI is reshaping how modern warehouses function—making them faster, more efficient, and highly responsive.

How AIDC is Leading AI Integration in Warehouse Systems 2025

AIDC Technologies India is at the forefront of bringing AI into warehouse operations across the country. With a solid background in automation, barcoding, RFID, and inventory control, AIDC is integrating AI features into its warehouse management systems. In 2025, the company is focusing on next-generation AI tools that enhance data visibility, reduce human error, and speed up decision-making processes. Their solutions are tailored for industries like manufacturing, pharmaceuticals, retail, and logistics.

Smart Storage Solutions: The AIDC Advantage in 2025

Smart storage is a key component of efficient warehousing. AIDC Technologies enables smart storage through AI-powered software that analyzes space usage, product frequency, and order patterns. This ensures that goods are stored logically and accessed quickly. With AI assistance, warehouse managers can make data-driven decisions about where and how to store inventory, maximizing both space and efficiency. AIDC's smart storage systems are built to adapt to the dynamic needs of modern supply chains.

AIDC’s AI-Powered WMS: Transforming Inventory Accuracy

One of the biggest warehouse challenges is maintaining accurate inventory. Traditional methods are often slow and prone to mistakes. Artificial Intelligence in Warehouse Management Systems helps overcome this issue. AIDC’s AI-powered WMS uses intelligent sensors, cameras, and real-time tracking systems to constantly monitor inventory levels. The system automatically updates records as items are added or removed, reducing discrepancies and saving time. This leads to better customer satisfaction and lower operational costs.

Real-Time Data Processing with AI in AIDC Warehouse Systems

In today’s competitive market, real-time information is crucial. AIDC Technologies India leverages AI to deliver instant insights into stock movement, order status, and delivery schedules. Their systems process large volumes of data from multiple sources and present it in a simplified dashboard. Managers can spot trends, respond to issues, and make faster decisions. With Artificial Intelligence in Warehouse Management Systems, AIDC offers businesses a way to stay ahead of the curve in real-time operations.

AI and Robotics in Warehousing: AIDC’s Automated Approach

Automation and robotics are rapidly becoming essential in modern warehouses. AIDC combines AI with robotic systems to automate repetitive tasks like picking, packing, sorting, and transporting goods. These AI-enabled robots are programmed to work around the clock with minimal supervision. They can also detect obstacles and reroute themselves, reducing workplace accidents. AIDC’s automated solutions not only improve efficiency but also cut down on labor costs, making warehouse management more sustainable.

Boosting Operational Efficiency with AIDC’s Smart Storage Technology

Artificial Intelligence in Warehouse Management Systems is not just about automation—it’s about intelligent automation. AIDC’s smart storage technology boosts overall warehouse performance by ensuring that every item is placed, retrieved, and moved in the most logical manner. The system learns over time, adapting to order frequency and seasonal changes. This leads to faster fulfillment rates and less congestion in storage zones. Businesses using AIDC’s AI systems report fewer delays and improved workflow.

Predictive Inventory Management Using AI by AIDC Technologies

Forecasting demand is critical for managing stock levels efficiently. AIDC uses AI algorithms to predict future inventory needs based on sales trends, historical data, and market conditions. This predictive approach helps avoid stockouts and overstocking. Artificial Intelligence in Warehouse Management Systems helps businesses be more proactive rather than reactive. AIDC’s predictive inventory management also aids in better budgeting and planning for warehouse operations.

AIDC’s Role in AI-Driven Warehouse Layout Optimization

Warehouse layout impacts how quickly products can be moved, packed, and shipped. AIDC Technologies uses AI models to analyze warehouse traffic, item popularity, and storage requirements to suggest the most efficient layout. These smart layout systems reduce unnecessary travel time for workers and robots, enhance safety, and improve throughput. As a result, businesses enjoy faster operations and reduced overheads—all thanks to Artificial Intelligence in Warehouse Management Systems by AIDC.

Smart Decision-Making in Warehouses with AIDC’s AI Algorithms

AI doesn’t just process data—it helps in making better decisions. AIDC integrates AI algorithms that analyze data in real-time and offer actionable recommendations. Whether it’s reordering inventory, adjusting shift schedules, or selecting shipping routes, AIDC’s systems make intelligent suggestions. This smart decision-making capability allows warehouse managers to focus on strategic planning instead of getting caught in daily operations.

Seamless AI and IoT Integration in AIDC Warehouse Solutions

AIDC Technologies believes that the future of warehousing lies in the fusion of AI and IoT (Internet of Things). Their solutions use smart devices, RFID sensors, and connected platforms to collect live data and feed it into AI systems. This integration allows warehouses to function as intelligent ecosystems—capable of self-diagnosing problems and triggering automated responses. Artificial Intelligence in Warehouse Management Systems powered by AIDC is creating truly connected warehouses in 2025.

Enhanced Order Fulfillment and Accuracy with AIDC’s AI Tools

Order fulfillment is the heart of warehouse operations. With AIDC’s AI tools, businesses can ensure that every order is processed correctly and delivered on time. The system automatically matches products with orders, verifies availability, and suggests optimal packing methods. This reduces errors and improves accuracy. AIDC’s AI-powered order processing tools are already helping retailers and e-commerce brands achieve faster delivery times and greater customer satisfaction.

Sustainable and Scalable Warehousing with AIDC AI Systems

Sustainability and scalability are key goals for warehouses in 2025. AIDC’s AI solutions are designed to grow with your business while reducing waste and energy consumption. The system minimizes unnecessary movement, reduces idle time, and optimizes resource usage. Artificial Intelligence in Warehouse Management Systems is making green warehousing possible, and AIDC is proud to lead this shift toward environmentally responsible automation.

Customer Success Stories: AI-Powered Warehousing by AIDC

Several clients of AIDC Technologies India have seen measurable improvements after implementing AI-based warehouse systems. From large retailers to logistics companies, businesses have reported enhanced speed, lower errors, and higher customer satisfaction. These success stories highlight how AIDC’s customized AI solutions are transforming real-world operations across sectors.

The Future of Smart Warehousing in India with AIDC Technologies

India's warehousing sector is evolving, and AI is at the core of this transformation. AIDC Technologies India is committed to helping businesses embrace Artificial Intelligence in Warehouse Management Systems for greater efficiency, accuracy, and scalability. With years of industry expertise and a passion for innovation, AIDC continues to shape the future of smart warehousing in India.

Book Now with AIDC Technologies India to upgrade your warehouse into an AI-powered smart facility.

#SmartWarehouseAI#AIinWarehouse2025#AIDrivenLogistics#WarehouseAutomationAI#NextGenWarehouse#IntelligentWMS#AIWarehouseTech

0 notes

Text

The Link Between Customer Satisfaction and Supply Chain Software

Businesses are constantly striving to improve customer satisfaction. One of the most overlooked yet critical areas that directly influences customer experience is the efficiency of the supply chain.Slow processes, frequent mistakes, and limited visibility can lead to customer dissatisfaction and weaken overall brand trust. This is where supply chain software becomes a game-changer. By automating and optimizing various logistics and fulfillment processes—especially demand planning and forecasting—companies can significantly enhance service levels, improve delivery accuracy, and create smoother customer interactions. When operations align with customer expectations, satisfaction becomes a natural outcome.

Enhancing delivery performance and accuracy

Customers now demand complete and timely deliveries. Any delays or errors can lead to dissatisfaction, damaging reviews, and a loss of trust in your brand. With the help of supply chain software, companies can monitor real-time data and track goods from the warehouse to the doorstep. Features such as automated inventory control, smart routing, and delivery status updates ensure that the right products reach the right place at the right time.

Moreover, integrating demand planning and forecasting into the supply chain system allows businesses to anticipate customer needs more effectively. By analyzing historical data and current market trends, companies can prevent overstocking or stockouts, which directly impacts customer satisfaction levels.

Improving inventory management for better service

Nothing frustrates a customer more than discovering a product is out of stock after they have placed an order. Efficient inventory management plays a vital role in reducing such scenarios. Supply chain software provides visibility into stock levels across multiple locations, enabling businesses to fulfill orders faster and more accurately.

Advanced demand planning and forecasting modules allow supply chains to respond proactively to seasonal demand, promotional campaigns, or sudden market shifts. This capability improves fulfillment rates, reduces backorders, and ensures customers receive what they want, when they want it.

Enabling proactive customer communication

Customers appreciate transparency. They want timely updates about their order status, expected delivery dates, and any disruptions that may arise. Through supply chain software, companies can automate notifications and updates via email or SMS, keeping customers informed throughout the fulfillment process.

In addition, modern supply chain software integrates advanced tracking and communication features that significantly improve transparency and ensure greater accountability across operations. This proactive approach builds trust and reassures customers, ultimately elevating satisfaction and retention.

Supporting long-term loyalty and brand reputation

Efficient supply chains do more than just fulfill orders—they shape the overall brand experience. When deliveries are reliable, returns are hassle-free, and inventory is always available, customers are more likely to stay loyal. Implementing robust demand planning and forecasting practices within the supply chain helps ensure consistency in service, which is crucial for building long-term trust.

Moreover, an efficient and transparent supply chain showcases a company's reliability and operational excellence. In the long run, this strengthens brand reputation and fosters greater customer loyalty and support.

Customer satisfaction is no longer solely a function of marketing or customer service—it is deeply connected to operational efficiency. By investing in supply chain software and leveraging its demand planning and forecasting capabilities, businesses can streamline operations, respond to customer needs proactively, and exceed expectations. In a world where customer experience defines success, aligning supply chain performance with customer demands is not optional—it is essential.

1 note

·

View note

Text

Santosh Kumar Sahu: A Visionary Revolutionizing India’s Agricultural Logistics

India’s agricultural landscape has long been plagued by inefficiencies — from post-harvest losses to fragmented supply chains. Enter Santosh Kumar Sahu, the driving force behind Go Green Warehouses, whose revolutionary vision and innovative strategies are transforming agri-logistics across the nation. Combining his deep agricultural expertise, technological insights, and commitment to sustainability, Santosh Kumar Sahu is spearheading a revolution, integrating AI-empowered systems to empower farmers and maximize efficiency.

From Rural Roots to Leadership in Agri-Tech

Born in a small village in Odisha, Santosh Kumar Sahu pursued agricultural sciences at OUAT, then honed his management skills with an MBA in IT and agriculture from DA-IICT. Over 18+ years, he amassed rich experience at Godrej Agrovet, Reliance Retail, NCML, and Krishidhan Seeds. But it was in 2018 that he teamed up with Maulik Shah to launch Go Green Warehouses — marking the turning point in India’s agri-logistics sector.

AI Meets Warehousing — A Smart Evolution

Under the leadership of Santosh Kumar Sahu, Go Green Warehouses is not just expanding its physical footprint; it’s innovating with digital infrastructure. By deploying AI-powered inventory management systems, predictive analytics for demand forecasting, quality control automation, and smart monitoring using IoT sensors, Santosh Kumar Sahu ensures that warehouses can dynamically optimize storage, reduce spoilage, and offer real-time dash boarding to farmers and traders.

These AI tools streamline operations, cut human error, and improve transparency — fostering trust among stakeholders while reducing costs and enhancing farm incomes.

Holistic Agri-Logistics — Beyond Storage

The ecosystem built by Santosh Kumar Sahu goes far beyond storage facilities:

Collateral Management & Commodity Finance: Enables farmers to leverage their stored produce as collateral for loans.

Post-Harvest Services: Sorting, grading, and quality assurance are embedded into each repository.

Market Linkages: Digital interfaces connect farmers and FPOs directly with buyers, avoiding exploitative middlemen.

Vertical Integration: Expansion into commodity testing, agro-processing, 3PL services, and agritech solutions powered by AI.

This end‑to‑end model not only slashes post-harvest losses but also empowers small and marginal farmers with financial inclusion and market access.

A Network of Green Warehouses

Under Santosh Kumar Sahu’s guidance, Go Green Warehouses has grown from a single operation in Gujarat in 2012 to a network spanning 600+ warehouses across 24+ states, serving over 4,000 farmers and FPOs. By 2025, the company aims to emerge as India’s largest agri-storage provider — and potentially expand globally. AI-driven expansion planning, risk monitoring, and operational efficiency are key to this ambitious roadmap.

Leadership Rooted in Trust and Sustainability

Trust forms the foundation of Santosh Kumar Sahu’s leadership. He emphasizes transparency through what they term the “8 Cs of Trust” (clarity, compassion, character, competence, commitment, connection, contribution, consistency). This philosophy ensures that every stakeholder — from warehouse staff to rural farmers — feels respected and heard.

He fosters a learning culture, empowering employees to experiment and innovate. Failures are treated as lessons — an empowering approach that fuels creativity and ensures continuous improvement in both logistics and tech.

Sustainability at the Core

Environmental stewardship is a non-negotiable for Santosh Kumar Sahu. Under his stewardship, Go Green Warehouses harnesses:

Renewable energy systems (solar panels, LED lighting)

Eco-friendly packaging and materials

Energy-efficient storage environments

Waste reduction initiatives

By integrating AI to monitor energy use and emissions, Santosh defines “green” not only as an aesthetic but as an operational ethos — saving both the environment and operational costs while enhancing brand image.

Farmer Empowerment Through Technology

AI-driven mobile apps and online dashboards roll out in regional languages, offering real-time info on:

Storage status

Quality grading results

Loan eligibility

Market trends and price forecasts

Under Santosh Kumar Sahu, these tools level the playing field for smallholders. Digital literacy training ensures that farmers actively use technology, driving adoption and inclusion.

H5: Collaborative Ecosystem Building

Collaboration lies at the heart of Santosh’s expansion strategy. Go Green Warehouses partners with:

Financial institutions for collateral-based lending

NABL-certified labs for quality assessments

Commodity exchanges and input vendors for market integrations

Agrotech start-ups for AI-driven hardware and data analytics

This networked model exemplifies Santosh Kumar Sahu’s vision of inclusive, tech-driven agricultural logistics.

Results and Impact

The integration of AI and sustainable practices under Santosh Kumar Sahu’s leadership has delivered impressive results:

Over 8000 crore INR worth of commodities stored

Farmer incomes increased through reduced spoilage and better pricing

Post-harvest losses slashed by up to 30–40%

600+ locations, servicing 4,000+ farmers and FPOs

Building trust with strong financial partnerships and premium clients

These metrics validate how Santosh Kumar Sahu’s model is not just visionary, but substantively transformative.

Looking Ahead

Santosh’s roadmap includes:

Further penetration into rural micro-warehousing

Full digital integration via AI and blockchain

Expansion into adjacent sectors — cold chain, pharma, FMCG storag

Exploring global partnerships at ports and logistic hubs

Santosh Kumar Sahu is also investing in R&D for novel agritech solutions — AI-based pest detection, predictive shelf-life analytics, and automated quality grading — all aimed at creating a smarter, more resilient agricultural ecosystem.

Leadership Advice from Santosh

Some key insights from Santosh Kumar Sahu:

1.Trust first — build value before pursuing profits

2.Patience and perseverance — renew focus even in the face of setbacks.

3.Empower your team — decentralize decision-making for innovation.

4.Listen and learn — stakeholder feedback fuels iterative improvements.

5.Aim for impact, not just scale — sustainability and empowerment are core success metrics.

Legacy of Transformation

More than a corporate leader, Santosh Kumar Sahu is an agent of socioeconomic transformation — uplifting rural communities, fostering sustainable development, and advocating for a digital agriculture revolution. His journey from a small village in Odisha to leading a pan-India agritech enterprise underscores the power of vision and purposeful execution.

0 notes

Text

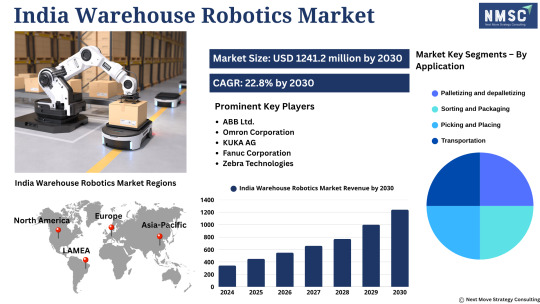

𝗗𝗜𝗗 𝗬𝗢𝗨 𝗞𝗡𝗢𝗪? 𝗜𝗻𝗱𝗶𝗮 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 is becoming one of the most underestimated goldmines in the automation space—and the smart capital is already flowing in.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗜𝗻𝗱𝗶𝗮 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 𝗶𝘀 𝘀𝗰𝗮𝗹𝗶𝗻𝗴 𝗮𝘁 𝘄𝗮𝗿𝗽 𝘀𝗽𝗲𝗲𝗱

𝗛𝗲𝗿𝗲'𝘀 𝘄𝗵𝗮𝘁'𝘀 𝗳𝘂𝗲𝗹𝗶𝗻𝗴 𝘁𝗵𝗶𝘀 𝗺𝗼𝗺𝗲𝗻𝘁𝘂𝗺:

1. 𝗠𝗮𝘀𝘀𝗶𝘃𝗲 𝘄𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗲𝘅𝗽𝗮𝗻𝘀𝗶𝗼𝗻 —India will need 500+ million sq. ft. of warehousing space in the next 5 years. 2. 𝗟𝗮𝗯𝗼𝗿 𝗰𝗼𝘀𝘁𝘀 𝗿𝗶𝘀𝗶𝗻𝗴, 𝗲𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝘆 𝗱𝗲𝗺𝗮𝗻𝗱𝘀 𝗴𝗿𝗼𝘄𝗶𝗻𝗴 —robotics is no longer optional. 3. 𝗠𝗮𝗸𝗲 𝗶𝗻 𝗜𝗻𝗱𝗶𝗮 + 𝗣𝗟𝗜 𝘀𝗰𝗵𝗲𝗺𝗲𝘀 + 𝗜𝗻𝗳𝗿𝗮 𝗯𝗼𝗼𝘀𝘁 = major tailwinds. Early-stage startups & deep-tech firms are gaining real traction with global VCs.

Still think robotics is a luxury in India? Think again.

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀: ABB Ltd., Omron Corporation, KUKA AG, Fanuc Corporation, JBT Corporation, GreyOrange, Bastian Solutions LLC, Zebra Technologies, Dematic, Honeywell International Inc, Vanderlande Industries B.V., Daifuku Co., Ltd., Murata Machinery, Ltd., YASKAWA ELECTRIC CORPORATION and others.

𝗧𝗵𝗶𝘀 𝗶𝘀 𝘆𝗼𝘂𝗿 𝘀𝗶𝗴𝗻𝗮𝗹.

If you're an investor looking for deep tech meets real-world scale, warehouse robotics is the entry point to India’s trillion-dollar logistics overhaul.

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

𝗧𝗵𝗲 𝗻𝗲𝘅𝘁 𝘂𝗻𝗶𝗰𝗼𝗿𝗻 𝗺𝗮𝘆 𝗻𝗼𝘁 𝗯𝗲 𝗮𝗻𝗼𝘁𝗵𝗲𝗿 𝗦𝗮𝗮𝗦 𝗮𝗽𝗽—𝗶𝘁 𝗰𝗼𝘂𝗹𝗱 𝗯𝗲 𝗮 𝗿𝗼𝗯𝗼𝘁 𝘀𝗼𝗿𝘁𝗶𝗻𝗴 𝗽𝗮𝗿𝗰𝗲𝗹𝘀 𝗶𝗻 𝗮 𝘄𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗻𝗲𝗮𝗿 𝗗𝗲𝗹𝗵𝗶. Are you watching? Or investing?

#IndiaRobotics#WarehouseAutomation#VCIndia#DeepTech#SupplyChainRevolution#Logistics#InvestorAlert#IndiaGrowthStory#SmartCapital#RoboticsStartup

0 notes